Drop Forged Conveyor Chain System For Powder Coating X348 X458 X678

Product Introduction

This model has a good space conveyor, wide scope, the work piece

can continuous operation at high temperature bake, harmful gas

area, spray booth.The machine has low power consumption, low

maintenance costs, durability, low noise, easy to operate.

Supply the regular overhead I-beam overhead conveyor chain

X348(150KG),F-100(300KG),X458(300KG),X678(500KG)

Product Specification

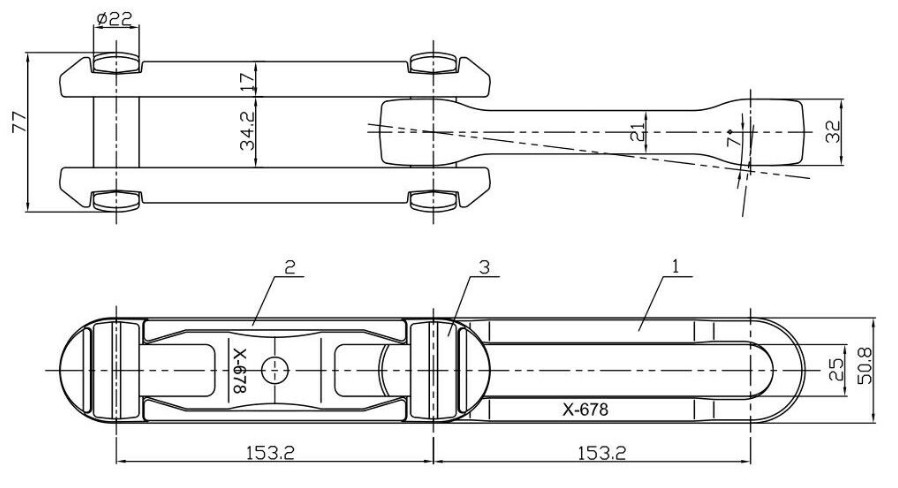

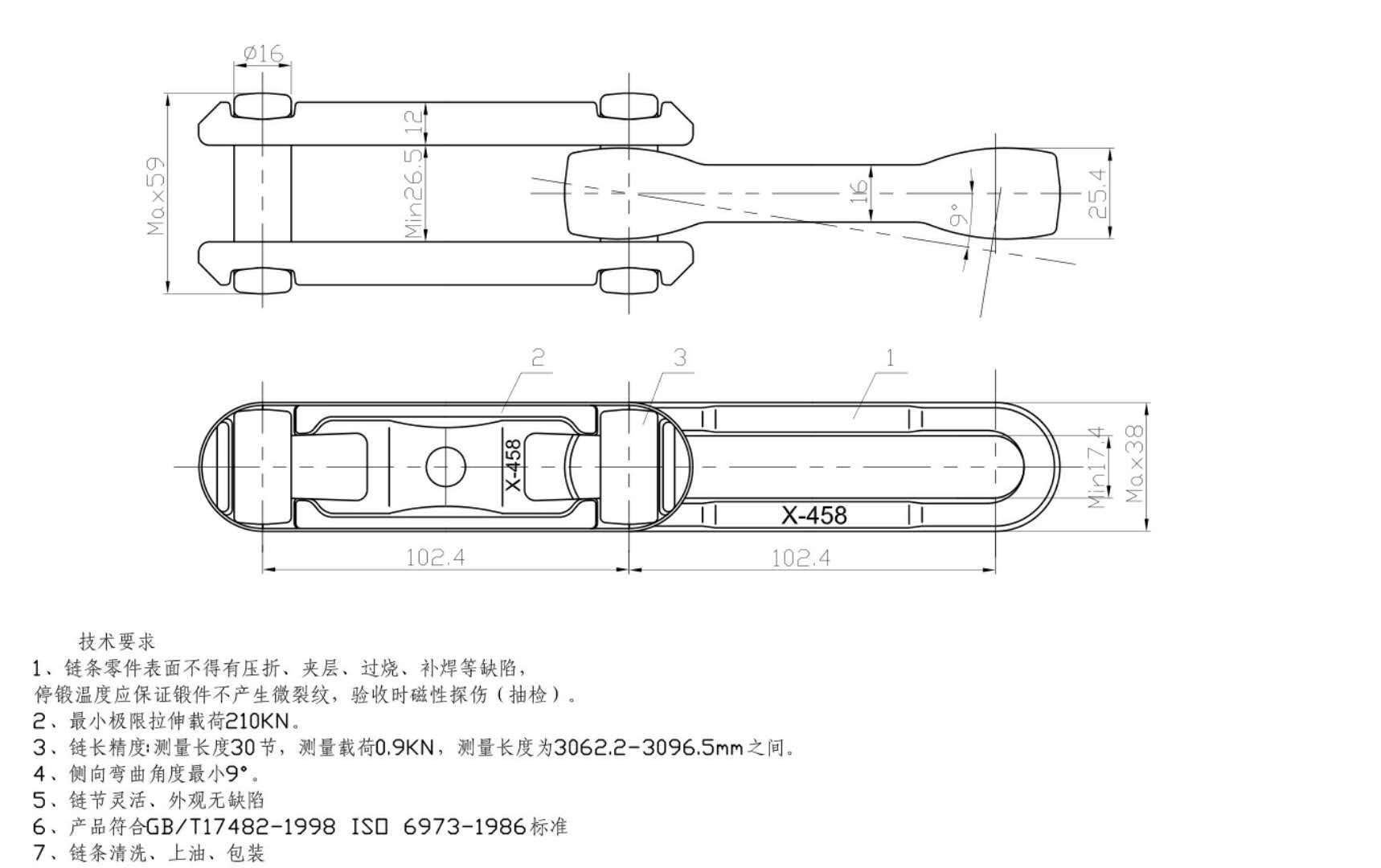

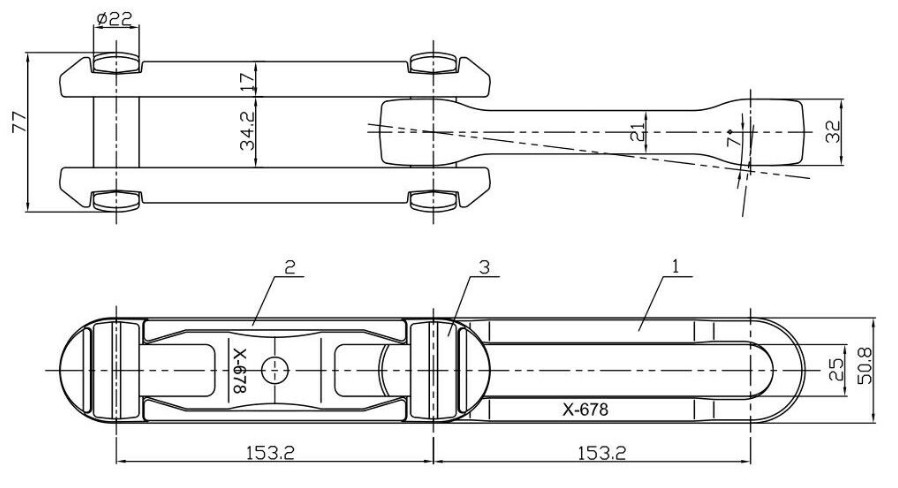

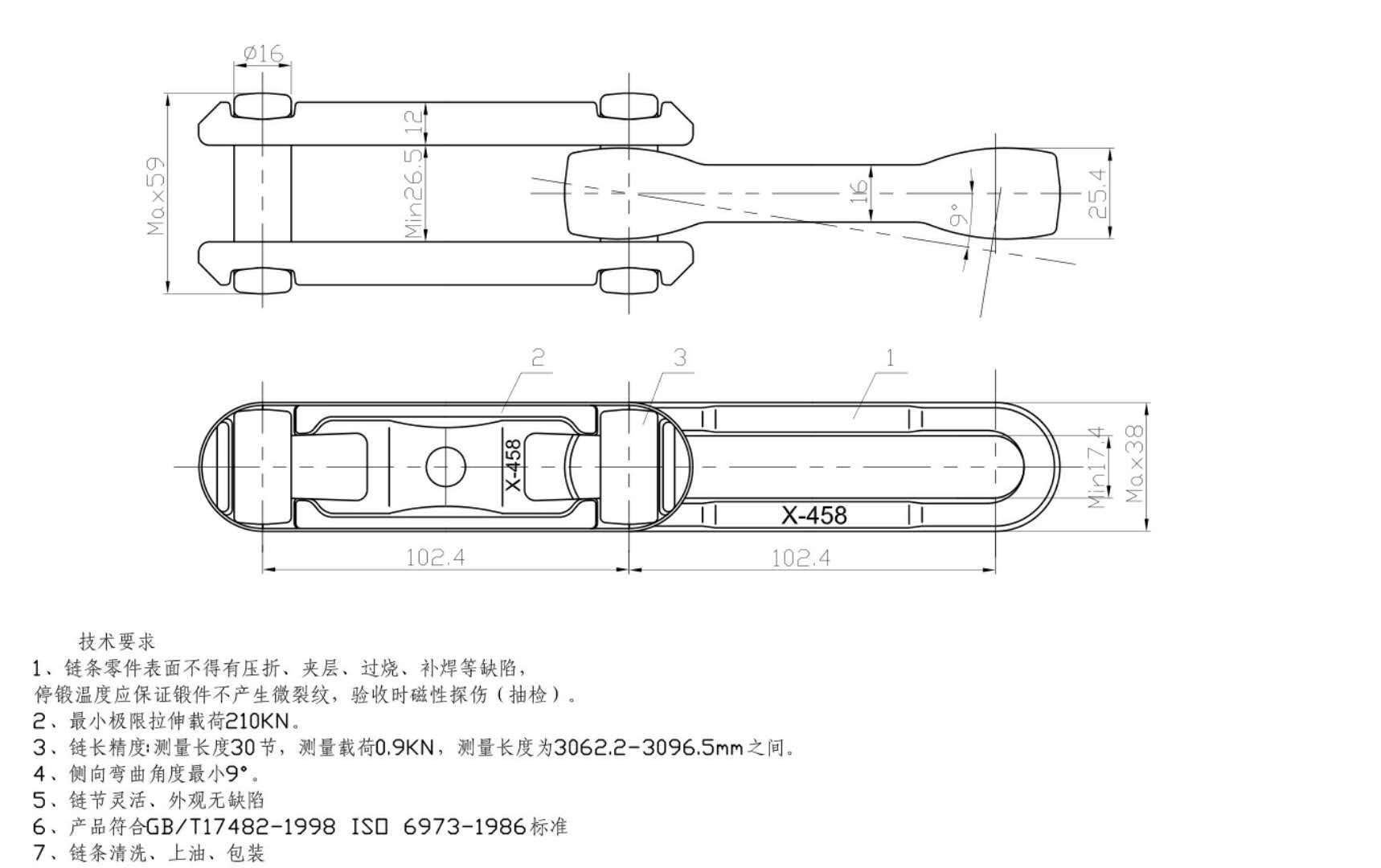

ITEN/MODEL | X348 | X458 | X678 |

Separation of suspension

| T=76.2 | T=100 | T=160 |

chain's weight

| 3.9 | 4.8 | 9.2 |

Chain's allowable pull force

| 110 | 220 | 400 |

Carriage limit load

| 300 | 500 | 800 |

Carriage allowable load

| 150 | 250 | 500 |

Track specification

| 8 or 10 | 12 or 14 | 14 or 16 |

Working temperature

| -20~200 | -20~200 | -20~200 |

Conveyor power

| 1.1, 2.2 | 1,5, 2.2 | 2.2, 3.4 |

Other Accessory

Hanger Turner : Employed with cross type or cross disk type hanger,

installed on the particular location of the route. When the cross

hanger walks to the redirector, the cross shaped arm touches it and

revolve 90°.

Track Flange: Used for the mutual connecting of the two tracks,

easy to construct and maintain with M10x20 bolt.

Track Install Hanger: While installing, squeeze the track inside

the hanger and tighten it with screws. It can increase the locating

and reliability and easy to dismantle.

Check Track: There is a hatch which can open the track, people can

dismantle, install, check or maintain the conveying chains though

the hatch. Each conveying route driving device should equipped with

one set check track, usually located between driving device and

take-up device for easy checking and maintenance.

High-temperature Chains Lubrican: Both high-temperature liquid and

solid lubricant is available. The liquid type is added to

oil-feeding cup or machine so as to lubricate the chain bearing,

while solid type is for chains where friction happens frequently,

thus to reduce the friction effect between chain and track.

15kg/bucket.

Manual /Automatic Oil Feeding Cup: Manual type: feed or drop some

lubricant on the chains and track with brush, amount of lubricant

is adjustable. Automatic type: Add a solenoid valve to oil groove

based on the manual oil feeding cup, automatic oil feeding is

realized though electric control.

Automatic Oil Sprayer: Specially designed for automatic conveying

chains. The sprayer is divided to main frame and oil-spraying

support, transparent oil pipes connecting two parts. This design is

convenient to choose the location of main frame and different types

of chains, oil spray support is adaptable. On other side, it’s

convenient to check oil-feeding situation via transparent oil pipe.

Application

I-beam overhead conveyor chain is close-loop continual conveying

equipment widely applied for continual convey of various industrial

work pieces, such as surface treatment, powder coating, paint

spraying, drying, oven, cooling room and plaing the finished

products off the line, furniture factories, bicycle

plants,electronic products factory, hardware factory.

Contact

Cici Lei

Whatsapp/ Wechat/ Mobile: +8618716717704

QQ: 2282925425