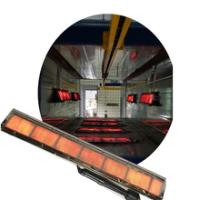

Industrial Gas Combustion Coating Powder Ceramic Infrared Catalytic

Gas Burner HD162

Product Introduction

There are three ways to transfer heat, Radiation, Convection,

Conduction and their thermal efficiency decrease in turn. Most

Equipment is mainly by convection to heat air first and then, the

heated air transfer to object. Heat loss is big.

But, differently, infrared gas burner heat object directly by

radiation and transfer rate will be much higher, usually cast iron

flameless infrared Catalyst Industrial Gas burner can save 20% gas

energy and cost.

Model

| Dimension | N.W. | Gas Type | Material | Heat Output | Gas Consumption |

| L*W*H(mm) | kg | | | Kcal/h | NG(m3/h) /LPG(kg/h) |

HD162 | 570*130*175 | 5.9 | NG/LPG | galvanized sheet, ceramic plate | 5400 | 0.49 0.45 |

Burner materials:

1. Shell: galvanized steel

2. Radiant part: cordierite honeycomb plates with black processed

rare-earth catalyst coated

3. Nozzle: brass

4. Up cover: stamped stainless iron

5. Bottom: iron cast

Advantage

1. Energy saving: conversion rate:≥90%

2. Environmental protection: CO≤80ppm;NOx≤10ppm;CHx≤50ppm

3. Whole combustion: 95% of energy released in the form of infrared

ray;heating the objects directly

4. Long life:≥11000hr

5. Easily installed

6. Flameless & smokeless

Notice

1. The inside casing measurement of oven should be confirmed when

choose Flameless ceramic asphalt plant infrared industrial lpg

heater model.

2. The intake-tube (or air blast pipe) and shell body can’t be

installed in the oven but bared in the air.

3. It is gas & air pre-mixed type, if baring air damper into air is

unavailable, pls leave some hole for enough air in.It needs to

leave a 4-5cm space between oven wall and ignition pin for

maintenance; Also keep the pinpoint distance from burner ceramic

surface 2~5mm.

4. A set of standard configuration of infrared catalytic burner is

infrared catalytic burner + ignition needle + pulse ignition +

solenoid valves.

5. Any installed position is ok, but when Flameless ceramic asphalt

plant infrared industrial lpg heater is on top or side, you should

keep a 15° gradient between the wall and burner ceramic surface so

that the heatwave will rise up smoothly.

Application

Coating industry dry (baking paint, powder drying), food baking

(dry and dehydrated), asphalt pavement and road and bridge concrete

fast -drying, latex molding, glass annealing and other oven and dry

machinery (tunnel -type oven, conveyor band oven, etc. ), Energy

saving reduction, environmental protection ...

Use high -energy automatic electronic pulse fireware and controller

to stabilize and safe

Company Introduction

Chongqing Haodong Technology Co., Ltd is a professional integration

of industry and trade who was built in 2005.We supply the solenoid

valve, pipe fitting & connector, kitchen valve, electric infrared

heater, water tap faucet and conveyor chain parts etc.

Good quality and reputation makes our products popular in both

domestic and overseas markets. Located in Chongqing City, southwest

of China, and has a branch factory in Zhejiang. We owns advanced

assembly lines, computer controlled injection machines, various

high precision test equipment, sterilizing equipment and laboratory

facilities.

Elaborately material selection, professional design, excellent

workmanship, sincerely service, what you want will be available in

our company. Sincerely to establish good, cooperative relations

with customers on the basis of equality, mutual benefit and common

development.

Factory Show

Contact

Cici Lei

Whatsapp/ wechat/ mobile: +8618716717704

QQ:2282925425